Understanding the Cost Factors in Customized Electronic Circuit Board Assembly

2025-09-22

1. Introduction to Customized Electronic Circuit Board Assembly

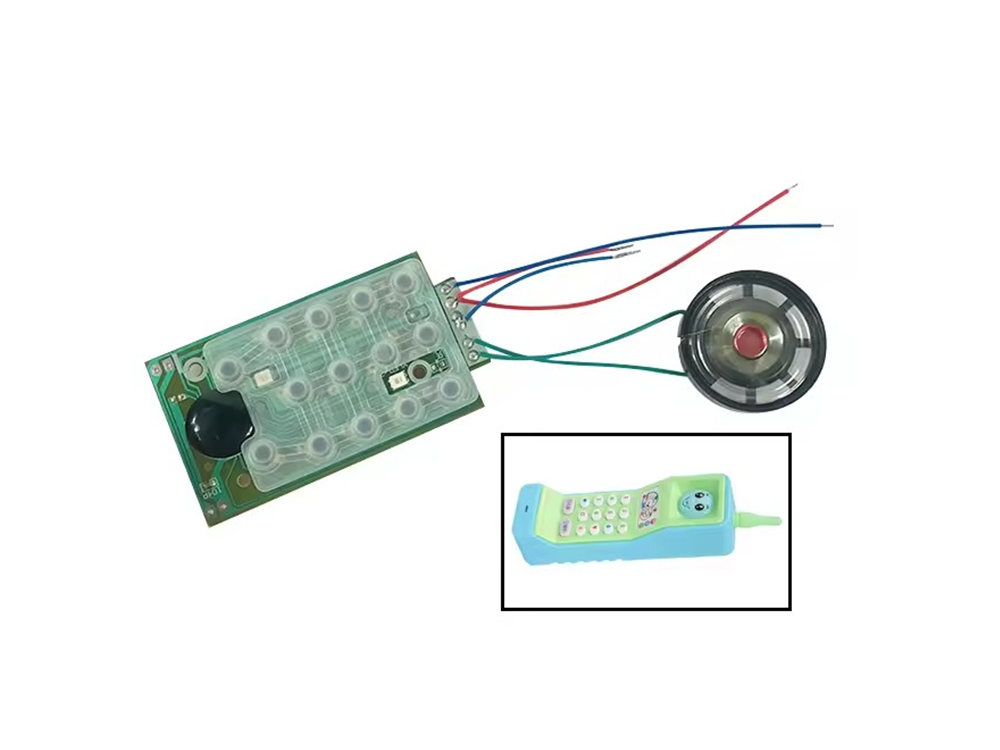

Customized electronic circuit board (PCB) assembly is the process of fabricating and assembling the components that make up a PCB according to specific design requirements. As electronic devices become more complex and feature-rich, the demand for tailored circuit boards is on the rise. This growing need has led to an intricate landscape of cost factors that must be navigated effectively.

Understanding these cost factors enables businesses to budget accurately and select assembly partners that align with their financial and quality expectations. Below, we will explore in detail the various components that contribute to the costs involved in customized PCB assembly.

2. Design Considerations Impacting Costs

Design considerations are fundamental to the cost of customized PCB assembly. The complexity of the design directly influences both the time required for production and the materials used.

2.1 Complexity and Layer Count

More complex designs often require additional layers, which can significantly increase costs. A single-layer PCB may suffice for simple applications, but multi-layer boards are essential for devices requiring higher functionality. Each additional layer adds to the manufacturing and assembly time, resulting in increased labor costs.

2.2 Component Placement and Routing

The placement of components and the routing of traces are crucial design aspects that impact costs. Tight component placement can reduce board size and material costs, but it may complicate assembly, leading to higher labor costs. Optimizing these factors can yield significant savings while maintaining performance.

2.3 Design for Manufacturability (DFM)

Implementing DFM principles during the design phase can streamline the assembly process and reduce costs. By considering how the board will be manufactured and assembled, designers can avoid costly revisions and ensure that the design fits within the assembly partner's capabilities.

3. Material Costs for Circuit Board Assembly

Material costs are a significant portion of the total expenses in PCB assembly. The selection of materials not only influences the functionality and durability of the circuit board but also its overall cost.

3.1 Base Materials

The choice of base material, typically FR-4 for standard PCBs, can vary based on the application. Specialty materials, such as aluminum or ceramic substrates, may be required for high-performance applications, leading to increased material costs.

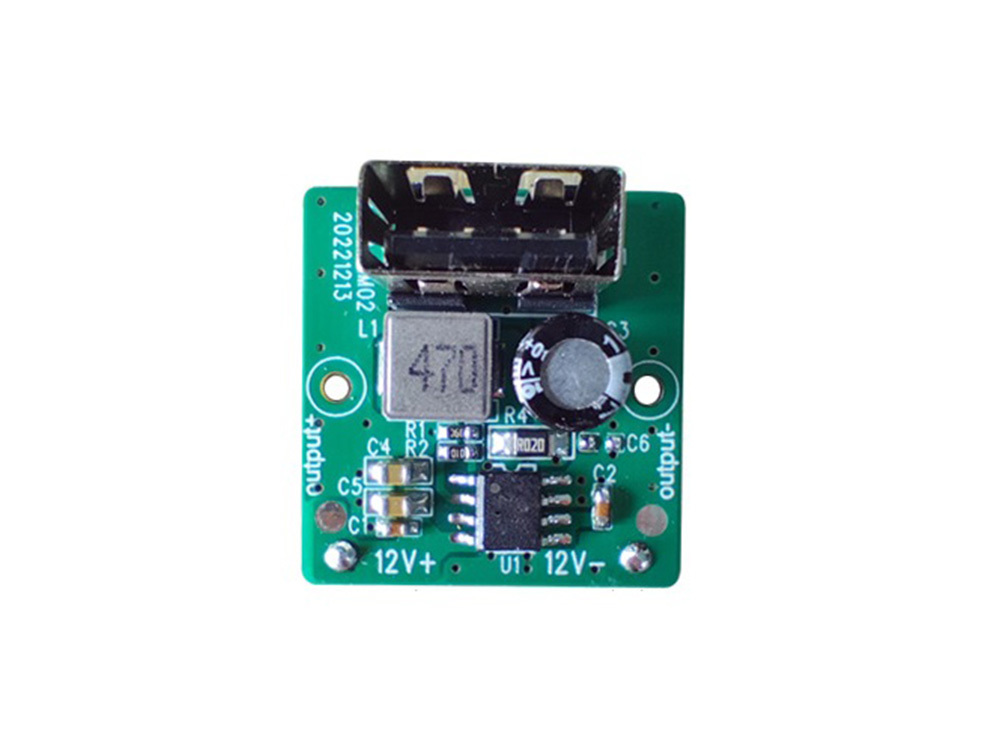

3.2 Components and Parts

The types of components used in the assembly also affect the total cost. Sourcing high-quality components might come at a premium, but it can lead to a more reliable product, reducing the likelihood of failure and warranty claims.

3.3 Sourcing and Availability

The sourcing process is influenced by supply chain dynamics. Components that are in short supply can lead to inflated prices, impacting the overall budget for assembly. Establishing good relationships with suppliers can mitigate some of these risks.

4. Manufacturing Process and Its Cost Implications

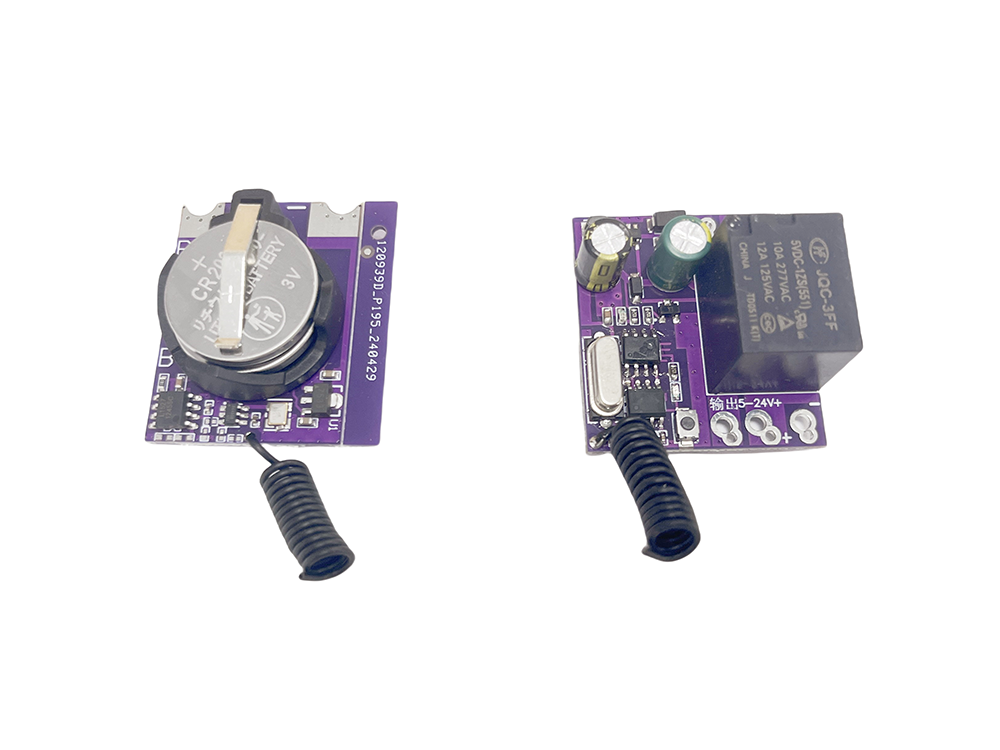

The manufacturing process chosen for PCB assembly plays a critical role in determining the final costs. Various methods, including surface mount technology (SMT) and through-hole technology, each have their own cost implications.

4.1 Surface Mount Technology (SMT)

SMT is widely used due to its efficiency and ability to accommodate high-density components. While SMT can reduce assembly time and labor costs, it may require specialized equipment, which can add to upfront costs.

4.2 Through-Hole Technology

Through-hole technology, while often more costly due to the additional labor required, is still favored for certain applications where durability is paramount. Understanding the pros and cons of each method is essential for cost-effective assembly.

4.3 Automated vs. Manual Assembly

Automated assembly processes can significantly reduce labor costs and increase consistency. However, the initial investment in automation equipment can be high. Balancing automation with manual processes is key to optimizing costs and assembly quality.

5. Labor Costs in Circuit Board Assembly

Labor costs are another critical factor in the overall expense of PCB assembly. Skilled labor is essential for ensuring quality and efficiency, but it comes at a price.

5.1 Skilled Labor Requirements

The complexity of the assembly process dictates the level of skill required. Hiring highly trained technicians can lead to higher labor costs but ensures that the assembly process meets stringent quality standards.

5.2 Location and Overhead Costs

Labor costs can vary significantly based on location. Regions with a high cost of living will naturally have higher labor rates, impacting the total cost of assembly. Outsourcing to areas with lower labor costs without sacrificing quality can be a viable strategy.

6. Quality Control and Testing Costs

Quality control is a non-negotiable aspect of PCB assembly. The costs associated with testing and quality assurance must be factored into the overall budget.

6.1 Testing Methods

Different testing methods, such as in-circuit testing (ICT) and functional testing, come with varying costs. Implementing a comprehensive testing strategy is essential to catch defects early in the process, preventing costly rework down the line.

6.2 Certification and Compliance

Depending on the industry, certain certifications (such as ISO and IPC standards) may be required. Achieving these certifications can incur additional costs but ensures product reliability and adherence to industry standards.

7. Scalability and Production Volume Effects

Scalability is a crucial consideration in cost management during PCB assembly. The production volume can significantly influence the unit cost.

7.1 Economies of Scale

Higher production volumes can lead to economies of scale, reducing the cost per unit. By planning for larger runs, businesses can optimize their costs and negotiate better terms with suppliers and manufacturers.

7.2 Prototyping vs. Mass Production

The transition from prototyping to mass production involves significant changes in cost structures. Prototyping often incurs higher costs due to small batch sizes and additional testing requirements. Understanding these dynamics is essential for budget forecasting.

8. Supply Chain Factors Influencing Costs

The supply chain plays a pivotal role in determining the costs of PCB assembly. Factors such as lead times and global events can cause fluctuations in pricing.

8.1 Lead Times and Inventory Management

Long lead times can delay projects and increase costs. Effective inventory management and communication with suppliers can mitigate these risks, allowing for smoother production schedules.

8.2 Global Events and Material Shortages

Global supply chain disruptions, such as those seen during the pandemic, can lead to material shortages and increased costs. Businesses must remain agile and adaptable to navigate these challenges effectively.

9. Conclusion

Understanding the cost factors in customized electronic circuit board assembly is essential for any business looking to innovate and optimize its electronic products. By carefully considering elements such as design complexity, material costs, manufacturing processes, labor expenses, and supply chain dynamics, companies can make informed decisions that enhance their bottom line. As technology continues to evolve, staying ahead of these factors will not only ensure competitive pricing but also foster higher quality and reliability in electronic devices.